Welcome to a world where precision meets innovation. Allow us to introduce you to Videojet Technologies Inc., a leading provider of advanced marking and coding solutions utilizing cutting-edge industrial printing technology. With a dedication to excellence, Videojet is revolutionizing the industry, providing product identification solutions and industrial coding equipment that surpass expectations. Whether you’re in need of advanced marking systems or industrial coding solutions, Videojet has the expertise and technology to meet your unique needs.

With Videojet Technologies Inc., you can expect nothing short of printing innovations that set new standards in the industry. Their commitment to excellence ensures that every mark is precise, allowing for accurate product identification and traceability. No matter the industry, Videojet’s industrial printing technology is designed to meet the demands of various sectors, including the pharmaceutical industry, food and beverage industry, and more.

When it comes to marking and coding solutions, Videojet Technologies Inc. is the go-to source. Their comprehensive range of products and services includes advanced marking systems, coding equipment, and industrial printing technology that deliver exceptional performance and reliability. From large-scale production to small batch coding, Videojet has the solutions to cater to your specific requirements.

Key Takeaways:

- Videojet Technologies Inc. is a leading provider of marking and coding solutions.

- Their advanced marking systems and coding equipment utilize cutting-edge industrial printing technology.

- Videojet is dedicated to excellence and precision in every mark.

- They offer a comprehensive range of products and services for various industries.

- With Videojet, you can expect printing innovations that set new standards in the industry.

Pack Expo Unveiling: Introducing New Products from Videojet Technologies Inc.

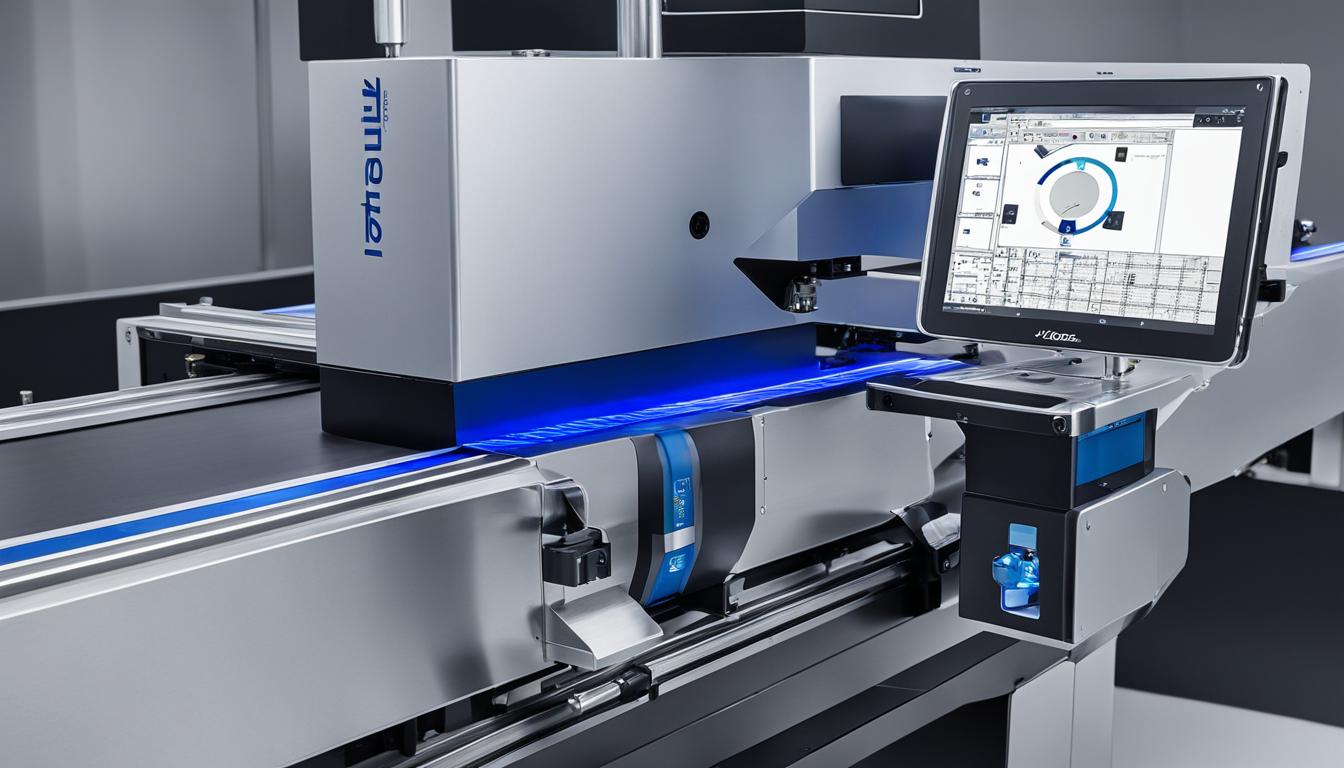

At Pack Expo, Videojet Technologies Inc. revealed an exciting lineup of new products, showcasing their commitment to innovation and excellence in the marking and coding industry.

One of the highlights was the introduction of the P3400 label printer applicator. This versatile device features a modular design, providing flexibility and ease of use. With an impressive standard 14″ unwind reel, the P3400 ensures increased uptime and efficiency. It is the perfect solution for industries that require precise labeling and accurate product identification.

Videojet Technologies Inc. also unveiled the Marsh 3100 and Marsh 1100 large character ink-jet printers. These printers are specifically designed to handle the printing of characters as large as 2.75″ and 0.66″, respectively. With a self-cleaning and self-maintenance system, these printers offer consistent and reliable print quality, reducing downtime and optimizing productivity.

The 1310 ink-jet printer introduced by Videojet Technologies Inc. is another standout product. This printer can start and stop without the need for time-consuming cleaning cycles, ensuring minimal downtime. Equipped with an automated backflushing nozzle, it further enhances productivity and efficiency in coding operations.

Lastly, Videojet Technologies Inc. unveiled the 3410 laser coder, an advanced solution for high-quality printing on various packaging materials. This laser coder excels in marking difficult-to-print substrates such as rubbers and plastics, ensuring clear, legible codes every time.

These new products from Videojet Technologies Inc. are a testament to their commitment to delivering cutting-edge solutions that meet the evolving needs of the marking and coding industry. With their extensive range of innovative products, including label printer applicators, large character ink-jet printers, ink-jet printers, and laser coders, Videojet Technologies Inc. continues to position themselves as a leader in the industry.

The Importance of Marking and Coding in the Pharmaceutical Industry

In the pharmaceutical industry, marking and coding play a crucial role in ensuring product traceability, accurate product identification, and regulatory compliance. For pharmaceutical companies, maintaining high standards of quality control is essential to meet track and trace requirements and provide safe and reliable products to consumers.

Videojet Technologies Inc., a leading provider of marking and coding solutions, offers innovative technologies tailored to the needs of the pharmaceutical sector. Their advanced marking systems enable precise printing of barcodes, text, and other crucial information on various pharmaceutical packaging materials, including cartons, labels, blister foils, and pouches.

By employing Videojet’s marking and coding technologies, pharmaceutical companies can effectively track their products throughout the supply chain. Traceability is vital in ensuring that the right product reaches the right customer, minimizing the risk of product recalls and enhancing patient safety.

In addition to traceability, accurate product identification is essential in the pharmaceutical industry. Videojet’s solutions enable reliable printing of unique identifiers such as serial numbers and batch codes, ensuring that products are accurately identified and managed throughout their lifecycle.

Regulatory compliance is another critical aspect of the pharmaceutical industry. With ever-evolving regulations, pharmaceutical companies must stay up to date with the latest standards and guidelines. Videojet’s marking and coding technologies are designed to help companies meet regulatory requirements and maintain compliance with industry regulations such as those set by the FDA and other regulatory bodies.

Benefits of Videojet’s Marking and Coding Technologies:

- Enhanced traceability, ensuring product authenticity and minimizing counterfeiting risks.

- Accurate product identification, facilitating efficient inventory management and recall processes.

- Improved quality control and assurance, enabling companies to meet stringent regulatory requirements.

- Streamlined operations and reduced downtime, optimizing productivity and efficiency.

- Flexible solutions adaptable to various packaging materials, sizes, and printing requirements.

By leveraging Videojet’s marking and coding technologies, the pharmaceutical industry can achieve greater operational efficiency, improved patient safety, and compliance with regulatory standards.

| Benefits of Videojet’s Marking and Coding Technologies | Impact |

|---|---|

| Enhanced traceability | Ensures product authenticity and minimizes counterfeiting risks. |

| Accurate product identification | Facilitates efficient inventory management and recall processes. |

| Improved quality control and assurance | Enables companies to meet stringent regulatory requirements. |

| Streamlined operations and reduced downtime | Optimizes productivity and efficiency. |

| Flexible solutions adaptable to various packaging materials | Sizes and printing requirements. |

Printing Technologies for Pharmaceutical Product Coding

In the field of pharmaceutical product coding, Videojet Technologies Inc. offers a diverse array of printing and marking technologies tailored specifically to meet the unique requirements of the industry. These cutting-edge solutions encompass a range of applications, ensuring accurate and reliable coding for various pharmaceutical packaging materials.

Innovative Printing Options

Thermal inkjet (TIJ) systems: Videojet’s TIJ technology provides high-resolution printing for linear barcodes, text, logos, and 2D codes like GS1 DataMatrix and QR codes. With the ability to deliver precise, readable codes on pharmaceutical packaging, TIJ solutions are an indispensable asset in maintaining traceability and enhancing product security.

Laser marking: Videojet’s laser marking solutions enable high-contrast, permanent coding on diverse pharmaceutical packaging materials, including cartons, bottles, labels, vials, ampules, tubes, and blister foils. The result is clear, indelible codes that withstand various environmental challenges and stringent regulatory requirements.

Thermal transfer overprinters (TTO): Integration into packaging machinery allows Videojet’s TTO systems to deliver high-resolution, variable content on labels and flexible packaging. This provides the flexibility required to accommodate evolving pharmaceutical product information.

Continuous inkjet systems (CIJ): With the versatility to print on almost any package type or product shape, CIJ systems are well-suited for a wide range of pharmaceutical applications. These systems enable comprehensive coding capabilities, ensuring critical information is accurately marked on pharmaceutical products.

Choosing the Ideal Solution

When selecting a printing technology for pharmaceutical product coding, it is essential to consider factors such as packaging material, code complexity, and production line speed. Videojet Technologies Inc. offers a comprehensive portfolio of solutions backed by extensive industry experience, providing pharmaceutical manufacturers with the flexibility to choose the most suitable technology for their specific coding requirements.

An Overview of Videojet’s Pharmaceutical Printing Technologies

| Printing Technology | Applications | Benefits |

|---|---|---|

| Thermal Inkjet (TIJ) | Linear barcodes, text, logos, GS1 DataMatrix, QR codes | High-resolution printing, traceability, product authentication |

| Laser Marking | Cartons, bottles, labels, vials, ampules, tubes, blister foils | High-contrast, permanent coding, compliance with regulations |

| Thermal Transfer Overprinters (TTO) | Labels, flexible packaging | High-resolution, variable content coding, adaptability to changing requirements |

| Continuous Inkjet Systems (CIJ) | Various package types and product shapes | Versatile coding capabilities, suitability for diverse applications |

By leveraging Videojet’s range of printing and marking technologies, pharmaceutical companies can ensure precise, legible, and compliant coding on their products, contributing to improved safety, efficiency, and overall customer satisfaction.

Printing Directly onto Drugs vs. Packaging: Considerations and Challenges

When it comes to printing in the pharmaceutical industry, there are considerations and challenges for both printing directly onto drugs and printing on packaging materials. Each approach has its own set of factors to take into account, ensuring the safety and effectiveness of the printed information.

When printing directly onto drugs, one crucial aspect to consider is ink compatibility. It is vital to select an ink that is compatible with the drug formulation and will not compromise its efficacy or stability. Extensive stability testing and reaction studies are often required to ensure that the ink does not have any adverse interactions with the drug. This ensures that the printed information remains clear and legible without impacting the product’s quality.

On the other hand, when printing on packaging materials, there are more options available in terms of ink or laser marking. However, it is equally important to ensure that the chosen ink or marking method does not pose any risks to the consumer. This requires thorough testing to evaluate extractables and leachables, which helps determine if any substances from the ink or marking material might transfer to the product inside the packaging and affect its safety or stability.

Both printing methods have their unique challenges and considerations but are crucial for maintaining product integrity, traceability, and regulatory compliance. By carefully selecting the appropriate ink or marking technology and conducting the necessary testing, pharmaceutical manufacturers can ensure that the printing process meets the highest standards of quality and safety.

Direct Printing onto Drugs:

Printing directly onto drugs involves considering ink compatibility with the drug formulation. Extensive stability testing and reaction studies are necessary to ensure the ink does not adversely affect the drug’s efficacy or stability.

Printing on Packaging Materials:

Printing on packaging materials offers more options, but manufacturers must ensure the ink or laser marking does not pose any risks to consumers. Extractables and leachables testing is conducted to evaluate the safety of the ink or laser marking on the product inside the packaging.

Ensuring High-Quality Variable Coding in the Pharmaceutical Printing Line

To ensure high-quality variable coding in the pharmaceutical printing line, it is crucial to have proper quality checks in place. Videojet Technologies Inc. recommends implementing an inspection system immediately downstream from the printer. This can be done using vision systems that are customized to meet the specific needs of the pharmaceutical industry. These systems can verify the accuracy and legibility of the codes printed and ensure that they meet the required standards. By incorporating such systems into the printing line, pharmaceutical manufacturers can ensure that their variable coding is of the highest quality.

| Advantages of Inspection Systems for Variable Coding in Pharmaceutical Printing Line | Implementation Steps |

|---|---|

| 1. Ensures code accuracy and legibility | 1. Install vision systems immediately downstream from the printer. |

| 2. Meets required standards and regulations | 2. Customize vision systems to meet the specific needs of the pharmaceutical industry. |

| 3. Reduces errors and rejections | 3. Set up verification procedures to check each code printed. |

| 4. Improves product traceability | 4. Ensure regular maintenance and calibration of vision systems. |

Legibility and Contrast: Colors and Containers in the Pharma Industry

In the pharmaceutical industry, legibility and contrast are key considerations when it comes to colors and containers. Videojet Technologies Inc. understands the importance of clear and readable codes in pharmaceutical packaging. That’s why they offer a wide range of inkjet colors that provide excellent legibility and contrast on different packaging substrates.

Advancements in UV laser technology have also revolutionized coding on white HDPE containers. With Videojet’s UV laser technology, it’s now possible to achieve high-quality, indelible black marks on white HDPE containers, including serial numbers and 2D barcodes. This ensures that the codes remain legible and scannable throughout the product lifecycle.

Whether you need to print UV-visible codes for internal traceability or GS1-compliant codes on cartons or bottles, Videojet has the technology to meet the legibility and contrast requirements of the pharmaceutical industry. Their innovative solutions ensure that critical information is clearly and accurately displayed, enhancing efficiency and enabling effective tracking and tracing of pharmaceutical products.

When it comes to choosing the right inkjet colors and marking technologies for your pharmaceutical packaging, don’t compromise on legibility and contrast. Trust Videojet Technologies Inc. to deliver exceptional quality and reliability, ensuring that your codes are easily readable and meet the highest industry standards.

| Advantages of Videojet’s Inkjet Colors | Benefits of UV Laser Technology |

|---|---|

|

|

Serialization and DSCSA Challenges in the Pharmaceutical Industry

Serialization and compliance with the Drug Supply Chain Security Act (DSCSA) pose unique challenges for the pharmaceutical industry. Ensuring accurate serialization is crucial to maintain product integrity, traceability, and regulatory compliance. Videojet Technologies Inc., a leader in advanced printing technologies, understands these challenges and offers solutions to help pharmaceutical companies overcome them.

With the implementation of serialization, pharmaceutical manufacturers must handle and manage large amounts of data. Videojet’s printing technologies are designed to handle this data efficiently while maintaining consistent readability. By utilizing their state-of-the-art printing solutions, companies can seamlessly integrate serialization into their manufacturing processes.

Verification is an essential step in ensuring compliance with the DSCSA. Videojet recommends implementing verification systems that validate the accuracy and authenticity of serialized codes. These systems provide real-time feedback, reducing the risk of errors and non-compliance. Videojet Technologies Inc. offers guidance on meeting regulatory requirements and assists companies in implementing efficient verification processes.

“Serialization and compliance are critical components in the pharmaceutical industry. Our printing technologies and expertise help pharmaceutical companies navigate the challenges associated with serialization and ensure compliance with the DSCSA.”

By partnering with Videojet Technologies Inc., pharmaceutical companies can tackle the challenges of serialization and maintain compliance with the DSCSA. Videojet’s advanced printing technologies and comprehensive support enable efficient serialization processes and reliable compliance verification.

| Benefits of Videojet’s Serialization Solutions |

|---|

| Efficient handling of large data volumes |

| Consistent readability of serialized codes |

| Implementation of robust verification systems |

| Guidance on regulatory compliance |

With Videojet’s serialization solutions, pharmaceutical companies can streamline their operations, improve supply chain visibility, and ensure compliance with regulatory requirements. By embracing Videojet’s expertise and advanced printing technologies, manufacturers can focus on delivering safe and high-quality pharmaceutical products to patients.

The Future of Packaging and Printing in the Pharma Industry

The pharmaceutical industry is constantly evolving, and so is the technology that supports it. As we look ahead, Videojet Technologies Inc. is at the forefront of packaging and printing advancements, envisioning a future that embraces cutting-edge innovations to enhance efficiency, traceability, and security in the industry.

Intelligent Data Management:

The future of packaging and printing in the pharma industry lies in intelligent data management. Videojet Technologies Inc. foresees a world where printers can communicate asynchronously with line control systems. This advanced connectivity enables faster notifications and higher throughput, streamlining processes and optimizing production efficiency.

UV Fluorescing Ink:

An emerging trend in the industry is the rise of UV fluorescing ink. Videojet Technologies Inc. recognizes the immense potential of this technology, especially for printing codes on vial tops. UV fluorescing ink offers excellent read rates under UV illumination while remaining invisible in normal lighting conditions. This advancement ensures clear and accurate data capture, enhancing internal traceability and facilitating efficient supply chain management.

Improved Internal Traceability:

Internal traceability is critical in the pharmaceutical industry to ensure product integrity and safety. The use of intelligent printers and UV fluorescing ink enhances the ability to track and trace products throughout the supply chain. By implementing advanced technologies, such as those provided by Videojet Technologies Inc., pharmaceutical companies can have greater visibility and control over their inventory, making it easier to identify and address any potential issues.

Enhanced Anti-Counterfeiting Measures:

As counterfeit pharmaceutical products continue to be a concern, the industry is actively seeking ways to combat this issue. Videojet Technologies Inc. recognizes the importance of anti-counterfeiting measures and provides solutions that help protect pharmaceutical products. With innovations like UV fluorescing ink, which is difficult to replicate, companies can implement enhanced security measures for their packaging and printing, safeguarding both their brand and consumers.

The future of packaging and printing in the pharma industry holds great promise. With Videojet Technologies Inc. leading the way, advancements in intelligent data management, UV fluorescing ink, internal traceability, and anti-counterfeiting measures will drive the industry forward, ensuring the safety and integrity of pharmaceutical products for years to come.

Conclusion

In conclusion, Videojet Technologies Inc. is a pioneer in the field of marking and coding solutions, providing top-notch industrial printing technology. With their unwavering dedication to excellence and precision, Videojet offers innovative products and services that cater to the diverse needs of various industries, particularly the pharmaceutical sector.

By leveraging their advanced marking systems and coding equipment, companies can achieve accurate product identification, ensure traceability, and achieve compliance with regulatory standards. Videojet Technologies Inc. remains at the forefront of the industry by continually pushing the boundaries of industrial coding solutions, setting new benchmarks for precision in every mark.

Whether it’s reliable printing on pharmaceutical packaging, implementing serialization and verification systems, or embracing future advancements in packaging and printing, Videojet Technologies Inc. stands as a trusted partner. Their commitment to excellence and their ability to deliver cutting-edge solutions make them the go-to choice for businesses seeking comprehensive marking and coding solutions in the industrial printing technology space.

FAQ

What does Videojet Technologies Inc. specialize in?

Videojet Technologies Inc. specializes in marking and coding solutions and industrial printing technology.

What products does Videojet offer for the pharmaceutical industry?

Videojet offers a range of printing and marking technologies specifically designed for pharmaceutical product coding, including thermal inkjet (TIJ) solutions, laser marking, thermal transfer overprinters (TTO), and continuous inkjet systems (CIJ).

What considerations are there when printing directly onto drugs?

When printing directly onto drugs, compatibility with the ink and its potential impact on the product must be taken into account. Stability and reaction testing is often required to ensure the ink does not affect the drug adversely.

How can pharmaceutical manufacturers ensure the quality of variable coding?

Videojet Technologies Inc. recommends implementing an inspection system downstream from the printer using vision systems customized for the pharmaceutical industry. These systems verify the accuracy and legibility of the codes printed.

What technologies does Videojet offer for achieving legibility and contrast on pharmaceutical packaging?

Videojet offers a range of inkjet colors that provide excellent legibility and contrast on different packaging substrates. They also offer UV laser technology for achieving high-quality, indelible black marks on white HDPE containers.

How can pharmaceutical companies maintain compliance with serialization requirements?

Videojet Technologies Inc. offers printing technologies capable of handling large amounts of data with consistent readability. Implementing verification systems is also recommended to ensure compliance with regulations.

What advancements does Videojet envision for packaging and printing in the pharmaceutical industry?

Videojet envisions a future with intelligent data management, where printers can communicate asynchronously with line control systems. They also see the rise of UV fluorescing ink for enhanced traceability and anti-counterfeiting measures.

Source Links

- https://global.videojet.com/wp-content/uploads/dam/pdf/NA – English/White-Paper/wp-keeping-pace-with-flow-wrapping-us.pdf

- https://www.packworld.com/machinery/coding-printing-labeling/news/13340286/videojet-releases-five-new-products

- https://www.pharmaceuticalprocessingworld.com/from-inkjet-to-uv-fluorescing-technology-is-making-a-huge-mark-in-pharmaceutical-printing/